Some minor tinkering to get the front end to 'work' as much as possible. I have gone back to 2-door torsion bars which are a smaller diameter and therefore have a softer spring rate. In order to get the torsion springs to deflect as much as possible I want minimal preload on them... ie make the ride height as low as possible without smashing panels too much, so have removed 1.5mm of material from the spindles. This brings the camber back into spec with the longer a-arms.

This is the static ride height

Also trimmed bumpstop to allow more uptravel

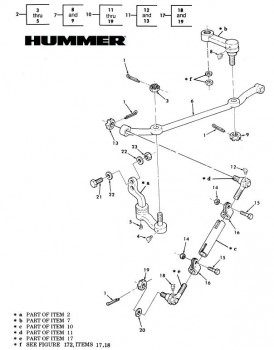

UCA bolt dimensions are M14x1.5x50

I have also done the 'bearing race mod' on the compression rods. I read about this on the 4x4parts forums.I like the LCA design for strength reasons because it sort of triangulates the control arm, but after well over 300,000kms, the bushing cups had disintegrated. They're not strong enough anyway.

I stared at it for a while and realised that how hard these things have to work in locating the the control arm and acting as a toe pivot point. Once the bushing cups flog out, the bushing is no longer located and the whole assembly is free to flop around the 27mm factory hole that it passes through. This leads to sloppy toe-in/out under high torque loads offroad, and also caster changes on road under braking/accel. as the whole control arm tries to shift fore/aft. It could also result in the rod failing completely if you did a jump etc.

Here is where it had started to contact the hole and rub away material

According to the manual there should be 2mm of free space around the bushing sleeve once its all installed. ie the sleeve should never really touch the hole if the bushing is located correctly.The hole was slightly deformed on one side so I opened it up a small amount. Note the carnage to the bracket from pivoting on a rock on the river. I just straightened it with a crowbar and BFH.

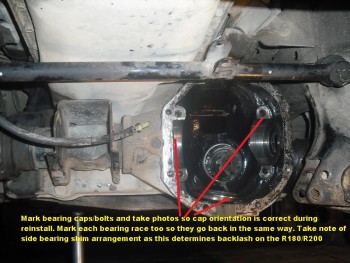

Then I went to visit Ants (fullthrottle) who blazed on these bearing races on both the front and back of the holes. Part number is LM67010, it is an easily available trailer wheel bearing race with keeps them seated perfectly snug. To do it properly, four are needed (2 per side of the vehicle). We also added some washers to the front side, just because there were there any we could.

Thinking about it more, maybe we should have put the washers on the reverse side. I might be (am) crazy but I think it will have changed the caster angle by putting the washers on the front side. Meh.. who gives a shist, more beef is better

Now the bushings are not moving anywhere.

I'm quite interested to see how far I can go with this so next I will be playing around with some air shocks, independently charged but also with a valve so that they can share the same air supply when needed. I saw this on the 4x4wire forum. I think I have found an air shock that is the same dimensions as the standard front shock. The idea here is that the linked shocks will a) support a small portion of the vehicle weight, to allow the ride height (torsion preload) to be reduced even further, b) allow for easily levelling if needed, and c) sort of create a lever action similar to a live axle. ie when as one wheel compresses it transfers all the air to the opposite side to encourage it to extend as much as possible. However Obviously in some situations you don't want this for stability/safety reasons, hence the valve.

Ultimately I think it would be awesome to do a coilover and get rid of the torsions altogether. I think the lower control arm would be up to the job, since on the Nissan design it already acts as the lever arm for the torsion spring. Obviously a new upper mount would need to be designed and fabricated. And In terms of packaging, it looks like there might be enough space. I was looking at the Gen 3 Pajero IFS.

It would be cool to find a donor coilover and do some measurements. The only difficulty I see would be adjusting ride height (camber). And Finding the right spring rate would be trial and error. Interesting food for thought though...