Checkerheads new project.

- Checkerhead

- Hard Yaka

- Posts: 463

- Joined: Sun May 25, 2014 11:20 pm

- Location: Christchurch

Re: Checkerheads new project.

Wow.

I think for that complexity, weight and expense I'd just build a bent link.

Though it's a good solution if I build it with mounts on top and find that the bush can't handle it.

I think for that complexity, weight and expense I'd just build a bent link.

Though it's a good solution if I build it with mounts on top and find that the bush can't handle it.

Supercharged VH45 Surf safari winch truck in the making

viewtopic.php?f=18&t=33527&hilit=checker%2A

viewtopic.php?f=18&t=33527&hilit=checker%2A

Re: Checkerheads new project.

The_wehi@hotmail.com

(027 788 1046)

pzj70,35's,Lockers,Winch and some stickers for added flex.

^^Soon to be on safari axles and 5.13's, 37's linked front and rear^^

Ln60 project (money pit) <-- Sold

Pzj77 Turbo/auto,33's .

(027 788 1046)

pzj70,35's,Lockers,Winch and some stickers for added flex.

^^Soon to be on safari axles and 5.13's, 37's linked front and rear^^

Ln60 project (money pit) <-- Sold

Pzj77 Turbo/auto,33's .

Re: Checkerheads new project.

Re the strength thing of the bar. Is it worth thinking about/looking at a profile cut flat plate bar out of something like 10-12mm bisalloy? Have no idea of it's structural properties etc, but it may be another option.

Ugly is a state of mind..... and the state of my truck!

- Checkerhead

- Hard Yaka

- Posts: 463

- Joined: Sun May 25, 2014 11:20 pm

- Location: Christchurch

Re: Checkerheads new project.

Yeah Rok, that's basically what I have been looking into and planning for the last few days.

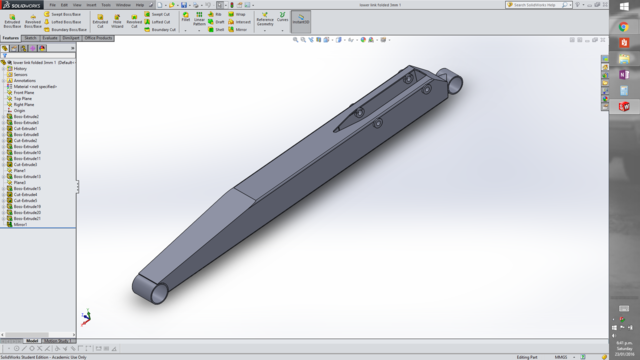

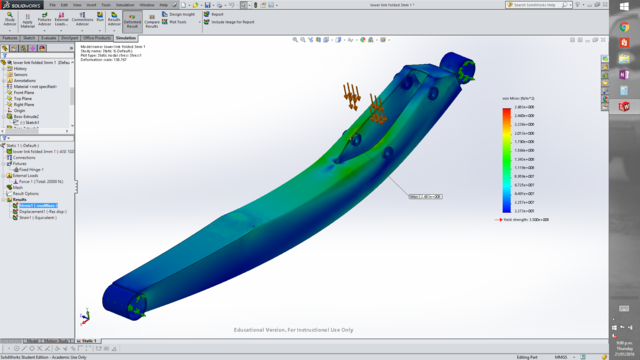

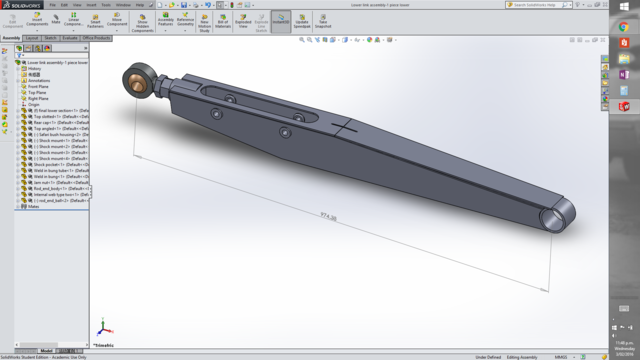

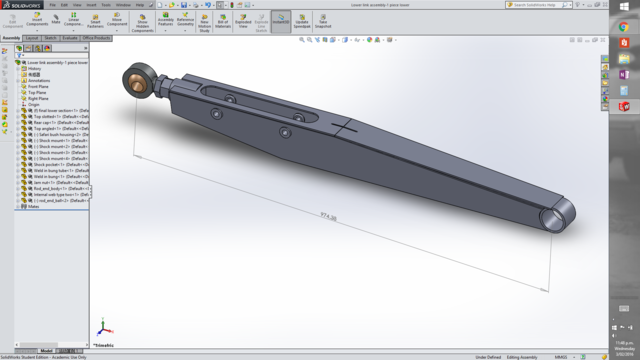

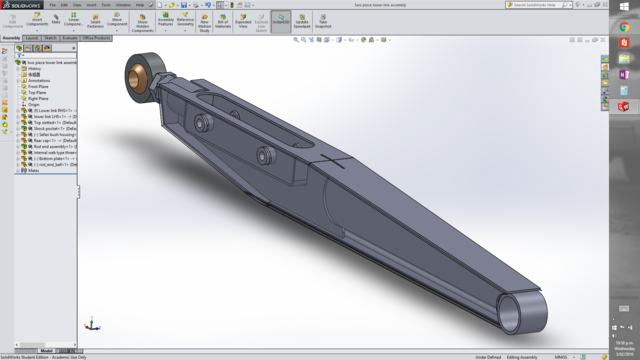

I drew this and tested this.

I'd build it by getting the lower three side folded out of one bit and welding the top on. In the test it's only made from 3mm. Max stress is 261 MPa and I would possibly be building it out of 700MPa "Strenx"

Might be a bit too much of a safety margin for my liking. Also note that Solid works thinks it is all one piece, so realistically there will be some higher stresses in the places where I weld it. There is no tube in this design (except where my weld in threaded bung will go at the axle end). I'm starting to move away from tube as it forces me to have a bunch of material near the center line of the arm, which does nothing for the strength (just like an I beam, it's the top and bottom of the I that work the magic, not so much the web in between).

Ignore the deformed shape. Solidworks magnifies the deformation so you can actually see where it's deforming.

Just need to have a think and refine some of my dimensions/positions and then get a price to have it cut and folded.

I drew this and tested this.

I'd build it by getting the lower three side folded out of one bit and welding the top on. In the test it's only made from 3mm. Max stress is 261 MPa and I would possibly be building it out of 700MPa "Strenx"

Might be a bit too much of a safety margin for my liking. Also note that Solid works thinks it is all one piece, so realistically there will be some higher stresses in the places where I weld it. There is no tube in this design (except where my weld in threaded bung will go at the axle end). I'm starting to move away from tube as it forces me to have a bunch of material near the center line of the arm, which does nothing for the strength (just like an I beam, it's the top and bottom of the I that work the magic, not so much the web in between).

Ignore the deformed shape. Solidworks magnifies the deformation so you can actually see where it's deforming.

Just need to have a think and refine some of my dimensions/positions and then get a price to have it cut and folded.

Supercharged VH45 Surf safari winch truck in the making

viewtopic.php?f=18&t=33527&hilit=checker%2A

viewtopic.php?f=18&t=33527&hilit=checker%2A

- Checkerhead

- Hard Yaka

- Posts: 463

- Joined: Sun May 25, 2014 11:20 pm

- Location: Christchurch

Re: Checkerheads new project.

Well I've been chipping away at the design of the lower link. Got it to where I'm sufficiently happy (if not stoked - both design and life involve so many compromises). Have emailed it to Sausager on here (with the "Rusty 413" build thread) as he is way more clever than me with this stuff. He will also get me a quote to cut it out of good steel and fold a few bits. Assuming he doesn't find any massive flaws in my design and I can afford it, then I will order them ASAP. The current design is along the lines of the previous pic but a touch more refined. I have halved the "shock mount to link centre line" dimension and thus halved the max torque that the link will see due to the shock. If I cant afford to do it properly, for now I will build them out of RHS and get everything cycled/mounted/tested and build them out of something better in a year or two (when it finally gets drivable).

So then I went to the garage this evening to look at where the shocks and rear stays might end up, now that I am a little more sure about where the lower shock mount will be. Basically I need to get both lower links built and bolted on before I can do much in the way of welding things in place and finalizing positions. Using the 16" coil over I should get 20.5" of travel out of it. So I should end up with 11" of up travel, about 8" of down and the rest is used up when at full articulation.

Tim, you were asking about rear over hang. I have about 270mm from the back of the tyre to the end of the chassis and about 550mm to the end of the upper tray/sides. This should all be about 800 of the ground at ride height so hopefully won't be too much of a drama.

So then I went to the garage this evening to look at where the shocks and rear stays might end up, now that I am a little more sure about where the lower shock mount will be. Basically I need to get both lower links built and bolted on before I can do much in the way of welding things in place and finalizing positions. Using the 16" coil over I should get 20.5" of travel out of it. So I should end up with 11" of up travel, about 8" of down and the rest is used up when at full articulation.

Tim, you were asking about rear over hang. I have about 270mm from the back of the tyre to the end of the chassis and about 550mm to the end of the upper tray/sides. This should all be about 800 of the ground at ride height so hopefully won't be too much of a drama.

Supercharged VH45 Surf safari winch truck in the making

viewtopic.php?f=18&t=33527&hilit=checker%2A

viewtopic.php?f=18&t=33527&hilit=checker%2A

Re: Checkerheads new project.

This is an absolutely awesome thread, I'm curious about one thing... I am surprised you are going for more uptravel than down travel... maybe suggesting the vehicle is designed for high speed, not crawling? Because IMO its pretty perfect crawling platform, just add another transfer case... its wide and low, and wheelbase/weight dist/susp are all really well set up... you have axles that will tolerate really tall tires and lockers....almost perfect rock crawler recipe...or are you going for high speed also?

ps Sausager is a real GC, and very good off road driver - as slow as possible, as fast as necessary

ps Sausager is a real GC, and very good off road driver - as slow as possible, as fast as necessary

TOYOTA - The Official Vehicle of ISIS!

And makers of the '92 Camry, where you got your first backseat handjob.

And makers of the '92 Camry, where you got your first backseat handjob.

- Checkerhead

- Hard Yaka

- Posts: 463

- Joined: Sun May 25, 2014 11:20 pm

- Location: Christchurch

Re: Checkerheads new project.

Thanks Lax.

From the out set I've been building this to be half winch challenge truck, half class six off road racer. I guess the ultimate goal is to do what ever NZ's version of Ultra4 ends up being, while still being road legal. I've recently and temporarily thrown the road legal thing out the window but it's still part of my end game.

So that's why I am going for more up travel. In theory I can lift the ride height a little for slower events, but I doubt I'll end up doing that. Hopefully find a happy medium and use it that way for every type of driving. I guess I could play with the bypass settings a bit.

From a crawling perspective, the belly is maybe a little low and certainly not very well tucked. I decided to compromise the flat belly a bit to make an over all lower CG (not much though), to make life a little more comfy inside the cab and to make the fabrication a little easier. In hind sight maybe I'd do it different next time.

From the out set I've been building this to be half winch challenge truck, half class six off road racer. I guess the ultimate goal is to do what ever NZ's version of Ultra4 ends up being, while still being road legal. I've recently and temporarily thrown the road legal thing out the window but it's still part of my end game.

So that's why I am going for more up travel. In theory I can lift the ride height a little for slower events, but I doubt I'll end up doing that. Hopefully find a happy medium and use it that way for every type of driving. I guess I could play with the bypass settings a bit.

From a crawling perspective, the belly is maybe a little low and certainly not very well tucked. I decided to compromise the flat belly a bit to make an over all lower CG (not much though), to make life a little more comfy inside the cab and to make the fabrication a little easier. In hind sight maybe I'd do it different next time.

Supercharged VH45 Surf safari winch truck in the making

viewtopic.php?f=18&t=33527&hilit=checker%2A

viewtopic.php?f=18&t=33527&hilit=checker%2A

- Checkerhead

- Hard Yaka

- Posts: 463

- Joined: Sun May 25, 2014 11:20 pm

- Location: Christchurch

Re: Checkerheads new project.

If you are bored of lower links and CAD, skip this post.

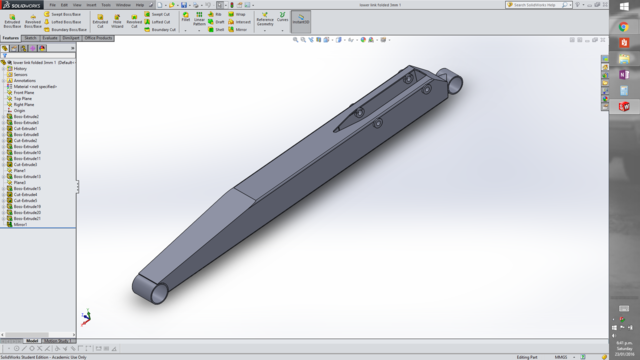

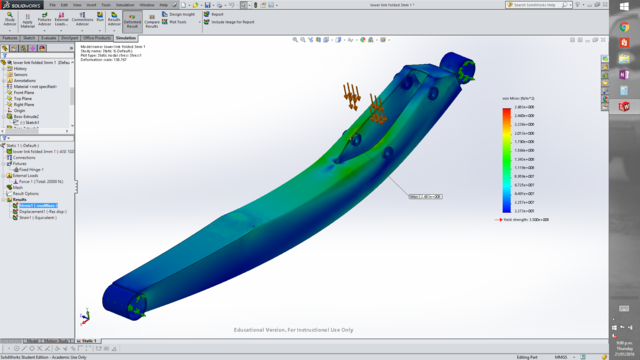

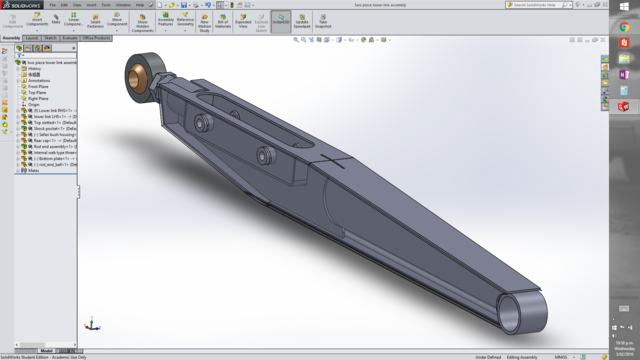

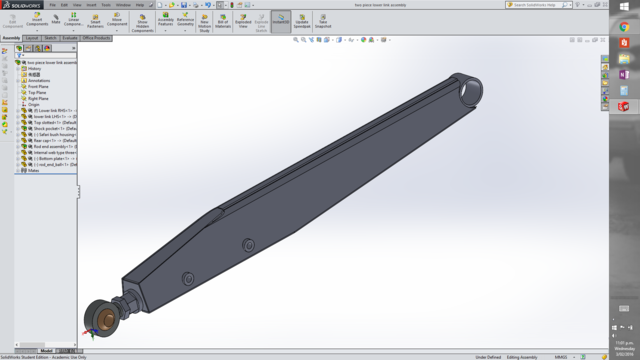

Well, after a bit more learning on Solidworks and a bit of a redesign due to my not fully understanding the manufacturing limitations, I think I have it all ready for some proper analysis.

I got to this point.

Then Suasager pointed out that we couldn't fit two tight radius bends as close together as I was planning (should have been obvious really). He suggested either a single big (25mm) radius in the bottom, or building the lower as two separate pieces (one each side). I went with the later option for a couple of reasons. One, I like the idea of the bottom of the link being flat(ish) rather than round and secondly the 25mm radius didn't suit me with regard to fitting the shock pocket in.

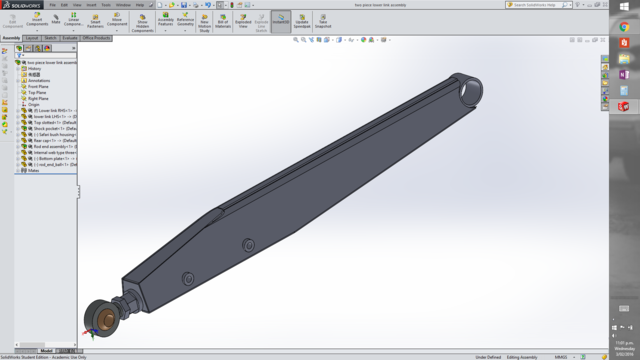

So now we have this, which is basically the same as above but with the lower made out of two pieces.

The side is transparent so you can see the "shock pocket" and "inner web" (which is notched with the "shock pocket" and the "top plate" to allow an external weld to grab both bits as well as helping me align things during assembly.

And a view from the bottom. You can see the seam where the lower two sections will be welded inside and out.

Well, after a bit more learning on Solidworks and a bit of a redesign due to my not fully understanding the manufacturing limitations, I think I have it all ready for some proper analysis.

I got to this point.

Then Suasager pointed out that we couldn't fit two tight radius bends as close together as I was planning (should have been obvious really). He suggested either a single big (25mm) radius in the bottom, or building the lower as two separate pieces (one each side). I went with the later option for a couple of reasons. One, I like the idea of the bottom of the link being flat(ish) rather than round and secondly the 25mm radius didn't suit me with regard to fitting the shock pocket in.

So now we have this, which is basically the same as above but with the lower made out of two pieces.

The side is transparent so you can see the "shock pocket" and "inner web" (which is notched with the "shock pocket" and the "top plate" to allow an external weld to grab both bits as well as helping me align things during assembly.

And a view from the bottom. You can see the seam where the lower two sections will be welded inside and out.

Supercharged VH45 Surf safari winch truck in the making

viewtopic.php?f=18&t=33527&hilit=checker%2A

viewtopic.php?f=18&t=33527&hilit=checker%2A

Re: Checkerheads new project.

What about a drain for the shock pocket ?

Looking very good

Looking very good

- Checkerhead

- Hard Yaka

- Posts: 463

- Joined: Sun May 25, 2014 11:20 pm

- Location: Christchurch

Re: Checkerheads new project.

Thanks Reece. I thought about a drain, but decided I was kidding myself. I think it would block up often and it will constantly be full of mud and stones which will need cleaning out anyway.De-Ranged wrote:What about a drain for the shock pocket ?

Looking very good

Supercharged VH45 Surf safari winch truck in the making

viewtopic.php?f=18&t=33527&hilit=checker%2A

viewtopic.php?f=18&t=33527&hilit=checker%2A

Re: Checkerheads new project.

Hi Aaron,

Apologies for not giving a ring, time just seems to fly by, looks like you are getting it sorted.

Good to see shock mount is almost in line with the centers of the 2 pivot points at each end.

Was thinking about drain point as well and agree that it will get blocked when in use but there will be times when it is all nice and clean after use that it will still fill up with water and possibly be a corrosion issue.

Regarding strength of the link, not sure how Solid Works does the analysis, just wondering how it deals with local buckling at the top of the shock pocket due to compression of the material as it is an open section, weaker than a closed section.

Regarding material strengths

Alot of the RHS sold in NZ is dual rated C350LO/C450LO which has a minimum Yield of 450 MPa, but need to be careful as there is some RHS that is sold that is only 350 MPa yield.

Cheers

Tim

Apologies for not giving a ring, time just seems to fly by, looks like you are getting it sorted.

Good to see shock mount is almost in line with the centers of the 2 pivot points at each end.

Was thinking about drain point as well and agree that it will get blocked when in use but there will be times when it is all nice and clean after use that it will still fill up with water and possibly be a corrosion issue.

Regarding strength of the link, not sure how Solid Works does the analysis, just wondering how it deals with local buckling at the top of the shock pocket due to compression of the material as it is an open section, weaker than a closed section.

Regarding material strengths

Alot of the RHS sold in NZ is dual rated C350LO/C450LO which has a minimum Yield of 450 MPa, but need to be careful as there is some RHS that is sold that is only 350 MPa yield.

Cheers

Tim

- Checkerhead

- Hard Yaka

- Posts: 463

- Joined: Sun May 25, 2014 11:20 pm

- Location: Christchurch

Re: Checkerheads new project.

Hey Tim.

I really don't know enough about solid works to answer the question about local buckling, but I'm not sure I could do it by hand either. Sausager will be all over it I'm sure.

I have looked into RHS a little, the size I need from steel and tube is just 350 but Asmuss had it in the dual grade (and a better price). I have a plan to build it out of RHS if I can't afford this flash cutting and folding business.

Guess you guys are right, any drain is probably better than no drain. It wont be hard to incorporate.

Arron.

I really don't know enough about solid works to answer the question about local buckling, but I'm not sure I could do it by hand either. Sausager will be all over it I'm sure.

I have looked into RHS a little, the size I need from steel and tube is just 350 but Asmuss had it in the dual grade (and a better price). I have a plan to build it out of RHS if I can't afford this flash cutting and folding business.

Guess you guys are right, any drain is probably better than no drain. It wont be hard to incorporate.

Arron.

Supercharged VH45 Surf safari winch truck in the making

viewtopic.php?f=18&t=33527&hilit=checker%2A

viewtopic.php?f=18&t=33527&hilit=checker%2A

Re: Checkerheads new project.

I'll more than likely block but it still lets the moisture out of the crap that gets stuck in there, that way you don't get as much corrosion potential same as a chassis bits catch mud but its dry and there isn't any corrosion lol well thats the theory

Just thought I'd mention it in case the drain hole acts like a stress riser (think thats the term) better you know and move the hole now than after they are built lol

Just thought I'd mention it in case the drain hole acts like a stress riser (think thats the term) better you know and move the hole now than after they are built lol

- Checkerhead

- Hard Yaka

- Posts: 463

- Joined: Sun May 25, 2014 11:20 pm

- Location: Christchurch

Re: Checkerheads new project.

Just realised that I aim for the exact opposite of this - as fast as possible, as slow as necessary.lax2wlg wrote: ps Sausager is a real GC, and very good off road driver - as slow as possible, as fast as necessary

Supercharged VH45 Surf safari winch truck in the making

viewtopic.php?f=18&t=33527&hilit=checker%2A

viewtopic.php?f=18&t=33527&hilit=checker%2A

- Checkerhead

- Hard Yaka

- Posts: 463

- Joined: Sun May 25, 2014 11:20 pm

- Location: Christchurch

Re: Checkerheads new project.

Supercharged VH45 Surf safari winch truck in the making

viewtopic.php?f=18&t=33527&hilit=checker%2A

viewtopic.php?f=18&t=33527&hilit=checker%2A

- Checkerhead

- Hard Yaka

- Posts: 463

- Joined: Sun May 25, 2014 11:20 pm

- Location: Christchurch

Re: Checkerheads new project.

It's been a while.

Tiny bits of progress have been happening.

I guess the next step was welding them up.

Here's what I started with. Then started putting it all together.

Tiny bits of progress have been happening.

I guess the next step was welding them up.

Here's what I started with. Then started putting it all together.

Supercharged VH45 Surf safari winch truck in the making

viewtopic.php?f=18&t=33527&hilit=checker%2A

viewtopic.php?f=18&t=33527&hilit=checker%2A

- Checkerhead

- Hard Yaka

- Posts: 463

- Joined: Sun May 25, 2014 11:20 pm

- Location: Christchurch

Re: Checkerheads new project.

Then had to cut some holes for the shock mounting points.

First method was a bit rough. Next method was better but not beautiful. Then was time to weld in the shock mounts. Then basically done.

First method was a bit rough. Next method was better but not beautiful. Then was time to weld in the shock mounts. Then basically done.

Supercharged VH45 Surf safari winch truck in the making

viewtopic.php?f=18&t=33527&hilit=checker%2A

viewtopic.php?f=18&t=33527&hilit=checker%2A

- Checkerhead

- Hard Yaka

- Posts: 463

- Joined: Sun May 25, 2014 11:20 pm

- Location: Christchurch

Re: Checkerheads new project.

I did weld a strap around the front bush housings.

Painted (in the free-est colour I had, would have preferred black). Here they are hanging to dry, with a standard Saf arm hanging up for comparison.

Safe to say the weld-in threaded bungs wont be coming out. One of them required lots of heat and everything the 20 tonne press had. The other one went in with just heat and banging it on the floor.

Supercharged VH45 Surf safari winch truck in the making

viewtopic.php?f=18&t=33527&hilit=checker%2A

viewtopic.php?f=18&t=33527&hilit=checker%2A

- Checkerhead

- Hard Yaka

- Posts: 463

- Joined: Sun May 25, 2014 11:20 pm

- Location: Christchurch

Re: Checkerheads new project.

Next it was time to see where the tops of the shocks could actually fit. I had a plan, but it didn't go a nice as I would have hoped.

I ended up trying to walk a very fine line between enough clearance from the chassis on the inside at one articulation, and enough clearance from the tyre on the outside at the other extreme of articulation.

Leaning the shocks forward a little helped, but I didn't want to go too far from vertical. I was already working the shocks hard in terms of mounting them part way up the control arm, thus increasing the leverage against them.

I had measured and mounted the bump cans. P.S. No idea how to rotate the attached images, but if you click on them they are rotated when they open.

I had measured and mounted the bump cans. P.S. No idea how to rotate the attached images, but if you click on them they are rotated when they open.

Supercharged VH45 Surf safari winch truck in the making

viewtopic.php?f=18&t=33527&hilit=checker%2A

viewtopic.php?f=18&t=33527&hilit=checker%2A

- Checkerhead

- Hard Yaka

- Posts: 463

- Joined: Sun May 25, 2014 11:20 pm

- Location: Christchurch

Re: Checkerheads new project.

Had even notched the bump can to make them sit nice and flush against that rear cage stay.

The old Saf suspension kept the tyres below the deck level (the bar in the pick). The new chassis/4 link did not  .

So to solve my shock and tyre/chassis clearance issue, and to reduce the tyre vs deck height problem, I needed to reduce articulation.

.

So to solve my shock and tyre/chassis clearance issue, and to reduce the tyre vs deck height problem, I needed to reduce articulation.

The way to do this without losing up travel was to move the bump cans wider. Damn it. So I did that. And ofcourse they were sweet at full compression/articulation, but the tyre rubbed the top of the cans at part compression/articulation. So then I angled them in a little, which solved the problem.

So then I angled them in a little, which solved the problem.

The way to do this without losing up travel was to move the bump cans wider. Damn it. So I did that. And ofcourse they were sweet at full compression/articulation, but the tyre rubbed the top of the cans at part compression/articulation.

Supercharged VH45 Surf safari winch truck in the making

viewtopic.php?f=18&t=33527&hilit=checker%2A

viewtopic.php?f=18&t=33527&hilit=checker%2A

- Checkerhead

- Hard Yaka

- Posts: 463

- Joined: Sun May 25, 2014 11:20 pm

- Location: Christchurch

Re: Checkerheads new project.

But I still could not fit my shocks in.

So I had to notch my already narrowed chassis. Heart breaking. But its done. Now I could finally have my shock in a reasonable position without smashing it on anything. So then I made up a crush tube type thing and drilled a hole for that in my rear cage stays. Note that the shock bolt is in single shear at the moment, but it won't stay like that. Also the rear stay will get some bracing. So with that sorted, time to finish or at least improve the axle end lower control arm mounts. Yes, its only 3mm. But it's 700 MPa and it will get an extra piece welded on the outside to increase thickness where the bolt goes through. With the new bump stops positions and shocks mounted, this is max articulation. Still better than standard even though I wasn't seeking to improve articulation in the rear end.

So I had to notch my already narrowed chassis. Heart breaking. But its done. Now I could finally have my shock in a reasonable position without smashing it on anything. So then I made up a crush tube type thing and drilled a hole for that in my rear cage stays. Note that the shock bolt is in single shear at the moment, but it won't stay like that. Also the rear stay will get some bracing. So with that sorted, time to finish or at least improve the axle end lower control arm mounts. Yes, its only 3mm. But it's 700 MPa and it will get an extra piece welded on the outside to increase thickness where the bolt goes through. With the new bump stops positions and shocks mounted, this is max articulation. Still better than standard even though I wasn't seeking to improve articulation in the rear end.

Supercharged VH45 Surf safari winch truck in the making

viewtopic.php?f=18&t=33527&hilit=checker%2A

viewtopic.php?f=18&t=33527&hilit=checker%2A

- Checkerhead

- Hard Yaka

- Posts: 463

- Joined: Sun May 25, 2014 11:20 pm

- Location: Christchurch

Re: Checkerheads new project.

And what you have all been waiting for (or maybe just me), it can support it's own weight.

It's sitting a little lower than ride height will be.

Supercharged VH45 Surf safari winch truck in the making

viewtopic.php?f=18&t=33527&hilit=checker%2A

viewtopic.php?f=18&t=33527&hilit=checker%2A

Re: Checkerheads new project.

That looks so cool!!!!

Re: Checkerheads new project.

an awesome looking truck!

1996 vzn185 surf, TRD supercharger, GQ SAS, 37s, 3" lift, 2 lockers, double cabbed + more happening.

2004 Jeep WJ 4.7 HO, 2" lift, 31s

Andrew 0272226292.

2004 Jeep WJ 4.7 HO, 2" lift, 31s

Andrew 0272226292.

- Crawlerer79

- Hard Yaka

- Posts: 305

- Joined: Sun Jun 12, 2016 3:38 pm

- Contact:

Re: Checkerheads new project.

Looking very cool

'The Big Truck' - 2001 TD5 Disco II

'Lando' - 1994 V8 Disco

'The Caramel Trophy Truck" - 1990 Disco Ex-Camel Trophy (?)

'Lando' - 1994 V8 Disco

'The Caramel Trophy Truck" - 1990 Disco Ex-Camel Trophy (?)

Re: Checkerheads new project.

Looks the shizzle bud

Ugly is a state of mind..... and the state of my truck!

- Checkerhead

- Hard Yaka

- Posts: 463

- Joined: Sun May 25, 2014 11:20 pm

- Location: Christchurch

Re: Checkerheads new project.

Holy heck I've moved house twice since that last update!

I really have very little to update. Have finished a Uni degree. I'm now a Mechatronics engineer. Employed as a Mechanical engineer at Invert robotics. invertrobotics.com. I have a fiancee. We own a house. I have a garage! So I guess stuff is progressing.

I have almost finished building a work bench I have purchased, but not quite installed a lathe I've done a couple of seasons co-driving in this thing. This is the creation of Andy (Team Tonka on here). He's a bloody clever guy and has done a great job. He's still improving it. I hope to be making some progress on my project, now that I've "finished" working on our house and have nearly got the garage sorted. Don't hold your breath, but I'll get an update on here on day.

I really have very little to update. Have finished a Uni degree. I'm now a Mechatronics engineer. Employed as a Mechanical engineer at Invert robotics. invertrobotics.com. I have a fiancee. We own a house. I have a garage! So I guess stuff is progressing.

It only took me 5 years after you posted that to get myself a tig.skidmark wrote:Looking good! My two cents, I recently brought a tig, and am loving it to be honest. Haven't done huge amounts with it, but steel seems to be straight forward. Ally well.....

But yea not having to clean up after myself is good.

I have almost finished building a work bench I have purchased, but not quite installed a lathe I've done a couple of seasons co-driving in this thing. This is the creation of Andy (Team Tonka on here). He's a bloody clever guy and has done a great job. He's still improving it. I hope to be making some progress on my project, now that I've "finished" working on our house and have nearly got the garage sorted. Don't hold your breath, but I'll get an update on here on day.

Supercharged VH45 Surf safari winch truck in the making

viewtopic.php?f=18&t=33527&hilit=checker%2A

viewtopic.php?f=18&t=33527&hilit=checker%2A

Re: Checkerheads new project.

No excuses now. Looking forward to seeing some more progress!

Getting a lathe & a TIG in the shed was a quantum leap for me in terms of what I could fabricate. You can design & build much cooler shit when you're not limited by the capability of your tools.

Cheers

Clint

Getting a lathe & a TIG in the shed was a quantum leap for me in terms of what I could fabricate. You can design & build much cooler shit when you're not limited by the capability of your tools.

Cheers

Clint

UZJ71 Landcruiser

Jeep J20 - 1UZ-FE powered (part owner)

KTM 640

If it breaks, build it stronger.

If it doesn't break, drive it harder.

Jeep J20 - 1UZ-FE powered (part owner)

KTM 640

If it breaks, build it stronger.

If it doesn't break, drive it harder.