Page 2 of 5

Re: my turbo fittment

Posted: Wed Jun 22, 2011 9:53 pm

by coxsy

you have to cert all engine powered conversions

Re: my turbo fittment

Posted: Sat Jun 25, 2011 8:17 am

by Hombrey

Mate I had a bunch of studs on my head snapped off. Ended up pulling the head and did 4!! Easy outs did not work even with the head off. Found drilling till close to stud size then put a tap in there and start tapping if your holes centered after about 1 - 2 full turns the whole stud turned then backed out the tap and the stud was stuck to it and wound out. Worked that way for 2 of the worst ones but your hole has to be central. good luck. Snapped studs really suck!! BTW I also have a water to air cooler and subaru rad etc if your interested. Cooler has never been used. Going to air to air.

Re: my turbo fittment

Posted: Sat Jun 25, 2011 2:15 pm

by coxsy

got the pump off better working in day light and warm

took radiator out as well full of crap the joys of bush bashing

and where we are with that stud

Re: my turbo fittment

Posted: Sun Jun 26, 2011 12:01 pm

by coxsy

had a talk to diesel mac next door, his idea undo engine mounts shove engine over to get better drilling angle,if all fails pull the engine rather than the head to get the stud out

Re: my turbo fittment

Posted: Sun Jun 26, 2011 7:27 pm

by crazyclark31

yeh that makes sense.

Just got a new truck and looks like am in for the same issue.

Let us know how ya get on can ya

Re: my turbo fittment

Posted: Sun Jun 26, 2011 9:50 pm

by speedylube

samething happened to us with my first conversion, you may as well pull motor out, you will have to do clutch anyway,

Re: my turbo fittment

Posted: Sun Jun 26, 2011 9:58 pm

by Pedro

coxsy wrote:the stud is two threads in, fa to weld to, so unless i go to bigger drills to get the whole stud out, its a fair pain in the butt, all so drain the radiator , and pull it out so i can get a puller in there for the drive gear,nothing has been touched on this engine for years

can try those reverse type drill outs instead

assuming you can actually get a drill in square, make a drill bush that bolts to the other holes, and aligns with the center of the broken bolt, and then drill out,

also studs generally work by the non threaded part "jamming" into the thread off the hole, drill Stud size or 0.5mm bigger approx 1mm deep, this should loosen the locking effect of the stud and enable it to wind out.

pedro

Re: my turbo fittment

Posted: Mon Jun 27, 2011 4:19 pm

by coxsy

oh i'm winning on the stud deptment, turbo clutch heavy duty was done a few months back, injecter pump now in the shop for boost anaroid , close to back running to fit that big fat turbo

Re: my turbo fittment

Posted: Thu Jun 30, 2011 9:55 pm

by olivercromwell

"You have to cert all engine powered conversions"

Just found the list of rules concerning engine modifications, you only need to have your vehicle certified by LVVTA if the increase in HP is over 20% and you've used the same engine. If you've repowered with a different engine with any increase in HP requiires a cert, $400 approx.

Re: my turbo fittment

Posted: Fri Jul 01, 2011 6:57 pm

by coxsy

socket welded to the sump tonight, one more thing done,

stud still to drill out, yah for weekends,

Re: my turbo fittment

Posted: Sat Jul 02, 2011 2:33 pm

by coxsy

Re: my turbo fittment

Posted: Wed Jul 06, 2011 2:14 pm

by darinz

I hate to tell you this since you've got the stud out, but when my one broke it was further in than that and we welded to it. Built it up with weld first then welded a nut to it and it came out really quick and easy. All up once the manifold was off it took about 10 minutes.

Have you thought about building a water to air I/C? I'm looking at one for mu tow wagon and one concept was building w2a as part of the intake manifold. The other advantage is it would take care of the cylinder filling imbalance you get at higher boost with the factory inlet.

Re: my turbo fittment

Posted: Wed Jul 06, 2011 3:59 pm

by crazyclark31

theres a few guys in aussie that have done that. they cut the top of the intake manifold and come up in a kinda triangle shape they curve round to the cooler. looks big but reckonm it would work really well. Most of the stuff i've seen is on the outer limits site

Re: my turbo fittment

Posted: Wed Jul 06, 2011 5:11 pm

by Taz

crazyclark31 wrote:theres a few guys in aussie that have done that. they cut the top of the intake manifold and come up in a kinda triangle shape they curve round to the cooler. looks big but reckonm it would work really well. Most of the stuff i've seen is on the outer limits site

Your not thinking of the Laminova intercoolers are you?

Re: my turbo fittment

Posted: Wed Jul 06, 2011 5:35 pm

by Landrover1953

Hi there, I have been a member for a while now but not used this forum, I am fitting the scarles turbo, same as the DSR that you have, doing that tonight, low mount tho, standard turbo manifold.

I also had the same stud issue, got Tom Taylor to come and remove it, came and did it on site, this guy is a legend, no issues, 1 hour, $120, fat lot of good that is to you now, sorry.

I have a large water to air intercooler on mine, plumbed into the rear heater system, doesn't add to engine temp, need small cerc pump, I used Subaru 12v pump.

Re: my turbo fittment

Posted: Wed Jul 06, 2011 5:44 pm

by coxsy

yes looked at one on trademe on watchlist, but get it running first then i will see,

sorry for lack of interest but a bit overloaded these days

Re: my turbo fittment

Posted: Wed Jul 06, 2011 7:46 pm

by crazyclark31

Taz wrote:crazyclark31 wrote:theres a few guys in aussie that have done that. they cut the top of the intake manifold and come up in a kinda triangle shape they curve round to the cooler. looks big but reckonm it would work really well. Most of the stuff i've seen is on the outer limits site

Your not thinking of the Laminova intercoolers are you?

Not them but something similar but WAY more simpler and cheaper

Re: my turbo fittment

Posted: Wed Jul 06, 2011 10:00 pm

by TD power

dont wind the boost over 15psi with the dsr turbo mate it will go bang

Re: my turbo fittment

Posted: Wed Jul 06, 2011 10:08 pm

by coxsy

running the preset boost level

but thanks for warning

Re: my turbo fittment

Posted: Thu Jul 28, 2011 4:38 pm

by coxsy

been to see my diesel and pump guy, the pump starting to look like a pump not a tray of peices

Re: my turbo fittment

Posted: Thu Jul 28, 2011 6:59 pm

by mikee

Want a video of your face coxsy when you start it up and when you go for your first drive

Re: my turbo fittment

Posted: Thu Jul 28, 2011 7:05 pm

by coxsy

a fair few hours of work still need before that happens

Re: my turbo fittment

Posted: Sat Jul 30, 2011 12:18 pm

by coxsy

got my torrano air cleaner modded and welded the dump pipe up, got james to do a measure last night as i lay under neath with the bend to get the lenght added 20mm just in case lol 20mm to long and need to rotate it a bit but only tacked so no major, found the double zz timing marks today too

Re: my turbo fittment

Posted: Mon Aug 01, 2011 5:08 pm

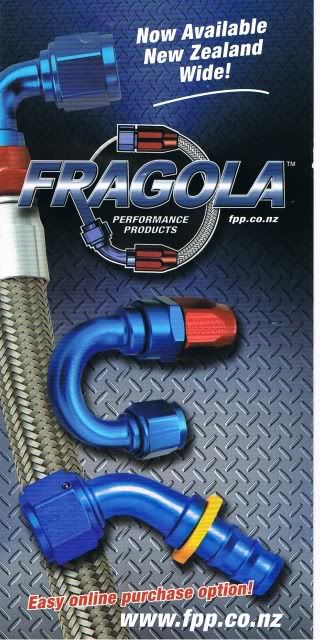

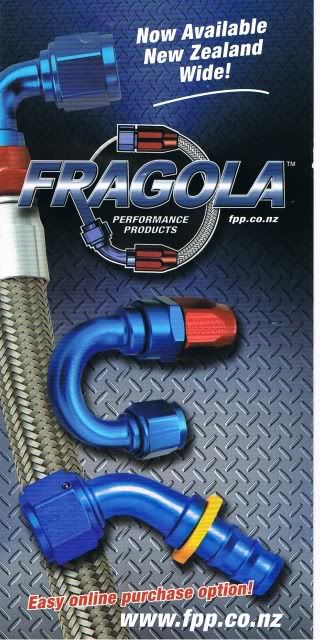

by coxsy

for mudhog these are the ali hose fittings i am using

Re: my turbo fittment

Posted: Mon Aug 01, 2011 6:15 pm

by wopass

coxsy wrote:

mean as zaust bro!!

Re: my turbo fittment

Posted: Mon Aug 01, 2011 6:22 pm

by LOLYF

Does that filtered exhaust stop the black smoke?

Re: my turbo fittment

Posted: Mon Aug 01, 2011 6:26 pm

by coxsy

oh pissing rain, best place to hang it and can paint it, though you could have a good point

Re: my turbo fittment

Posted: Tue Aug 02, 2011 10:55 am

by tgaguy1

coxsy wrote:

Coxsy, how are you getting your exhaust past your PTO shaft? I assume you are running 3" pipe. Got any photos?

Cheers

Jase.

Re: my turbo fittment

Posted: Tue Aug 02, 2011 12:30 pm

by muskie

tgaguy1 wrote:coxsy wrote:

Coxsy, how are you getting your exhaust past your PTO shaft? I assume you are running 3" pipe. Got any photos?

Cheers

Jase.

hey if you want a pic of my dump pipe with winch driveshaft cut out pm me, i am doing exactly the same install and made my 3'' exhaust (never again) last weekend. it is off the truck to paint at the mo so easy to take a pic for you.

Re: my turbo fittment

Posted: Tue Aug 02, 2011 5:02 pm

by coxsy

no need have enough room to get 2.5'' passed to shaft so running with that for awhile

had to add a 45* fitting to get the water house off the exhuast housing

and a view from underneath

its still temp sitting at the mo