I have finally had a guts full of nervously watching the oil pressure and nannering it up hills, so seeing as the Safari has sold, I thought it was time to fix the problem.

The old girls done LOOOOOOOOTS of K's. Like getting close to halfway round!!!!

A good bugger I know offered me a few options, one of which was a nice running motor in a crashed disco. We went and inspected it, it was in great condition with a new head and good hot oil pressure but due to some minor details such as the Discoveries having a electronic fuel pump like the 1KZ -te Surfs (eh UBZ

) and persuasion from the father in law, we left it alone in favour of working on the current engine.

So I went shopping at my favourite place again,

http://www.landroverspares.co.nz, who promptly got a package of goodies to my door step. 90% mechanical, with a couple of much need interior enhancements thrown in for good measure.

Full bottom gasket and seal set, oil pump gear set, big end bearing set, main bearing set, rear main seal, manifold gasket set:

So Friday night Sarah brought it into the work shop, I went and picked up Dave and his tools from his work shop, and we got stuck in.

Dave thought I might need more tools than what I have in my two draw box

Anyhow, fluids were dumped, stuff removed left right and center, and then it was time to put it up on the hoist to attack the nuts on the Turbo dump flange.

Friday night, weekend mission, the odds were definitely against us for getting those nuts off the Turbo flange with out a snapped stud!!!! Dave went digging in his monster tool box and produced a 1.5m long extension. That should do it he reckoned. Apparently its handy on 4x4 Chev Ambulances?? I was more impressed with the fact that someone could fit a 1.5m extension inside their tool box to start with!!!!

So with the flange sorted and no broken studs, it was time to hook it out of the hole. Its actually a fairly big unit when you see it dangling in mid air!!!

I rekon you could fit a 401 C.I Chev in here!!!

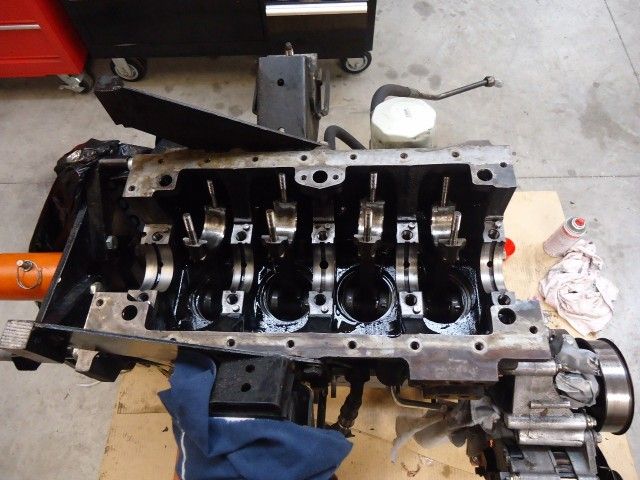

I'm not sure what happened to the next lot of pic's, today was a blur, but it got mounted to an engine stand, injectors pump and turbo removed to be reconditioned, crank removed etc etc

At the end of play today, it looked like this:

Rolled the race cars back in and it was time to go help Mudslut drop the motor back into the the Paj:

I roped the father in law in, and he lent his expertise and tools and measured all the crank shaft journals for me. All well with in spec. That's great on one hand, but bad on the other, were was my hot oil pressure going I wonder??

The next place to look was to crack open the timing cover and have a measure of the oil pump gears.

MEASURING NOT REQUIRED!!!!!!

The wear was immediately obvious.

Old pump on left, new on the right.

Can you see it?? Can you see the big steps worn in it??

Old pump gear tooth section:

New Pump gear tooth:

Its a good feeling when you find something wrong like that!!!!

So its the big clean up and more clean up, clean, prep, clean, clean, cleeeean, prep, and then start putting it back together tomorrow.

Maybe. Dumb Man Flu

cos that's almost what I do when reading DB's thread and looking at DB's pics......

cos that's almost what I do when reading DB's thread and looking at DB's pics......