Page 1 of 1

the print out for the rear axle

Posted: Tue Aug 17, 2010 3:05 pm

by coxsy

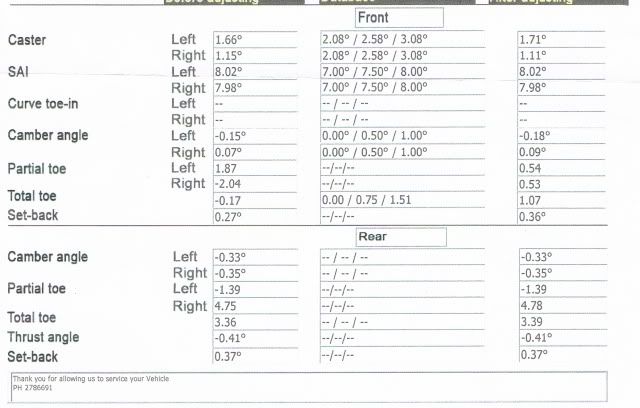

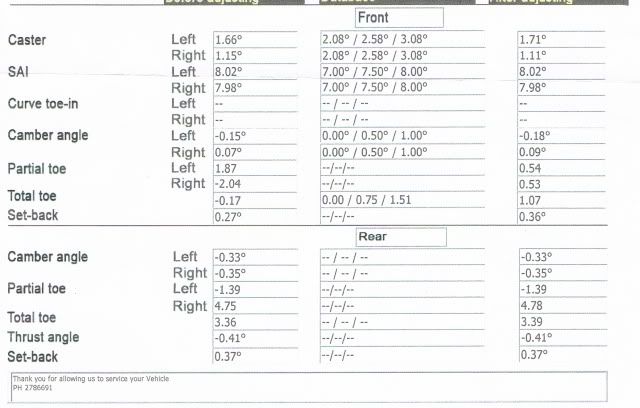

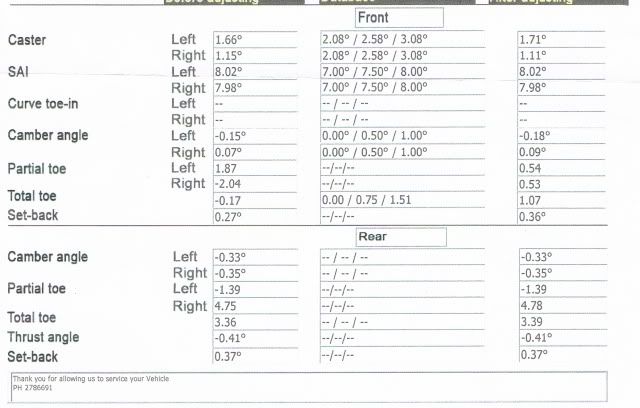

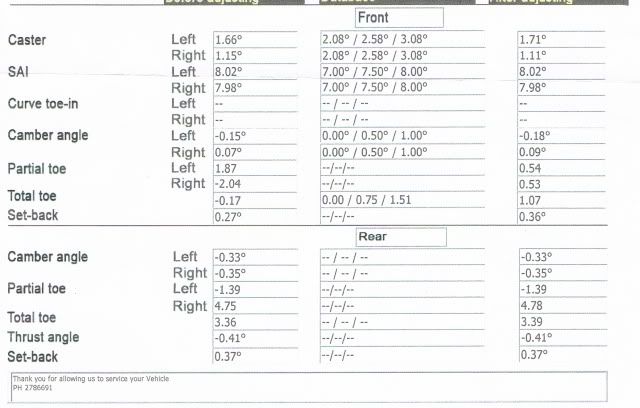

had a wheel alinement rear axle is taking a pounding

Re: the print out for the rear axle

Posted: Tue Aug 17, 2010 5:46 pm

by 1nzsafari

when i brought my safari i put new tyres on it and did 1 trip to chch from dunners and chew the back ones out, diff bent 19mm , a friend "s one bent 9mm

Re: the print out for the rear axle

Posted: Tue Aug 17, 2010 6:53 pm

by coxsy

well that means mine pretty good then only 4mm

Re: the print out for the rear axle

Posted: Tue Aug 17, 2010 8:17 pm

by Hombrey

How did you know you had a problem? My GQ has got a noise coming form the back but has had diff head rebuilt. Sound increases and decreases with speed and fluctuates like a fluctuating whine but its not from the diff head. Wheels both rebalanced and still same noise. Kinda annoying but been doing it for ages.

Re: the print out for the rear axle

Posted: Tue Aug 17, 2010 8:19 pm

by coxsy

because it was put on a new hi tec wheel alinement machine oh gross weight is 2468kg

Re: the print out for the rear axle

Posted: Tue Aug 17, 2010 11:11 pm

by Hombrey

Oh OK. So you did'nt have any tell tale noises you noticed? Bugger.

Re: the print out for the rear axle

Posted: Wed Aug 18, 2010 12:44 am

by IcedJohnno

Hombrey wrote:How did you know you had a problem? My GQ has got a noise coming form the back but has had diff head rebuilt. Sound increases and decreases with speed and fluctuates like a fluctuating whine but its not from the diff head. Wheels both rebalanced and still same noise. Kinda annoying but been doing it for ages.

How do you know it is not from the diff-head? Sounds very much like it. Usually this noise travels up and sounds as though it is coming from the transfer case.

Load dependant flutuating noise is generally the mesh being set wrong. There are many so-called experts that set these but I have seen many setters who have little idea. Choose wisely...

Re: the print out for the rear axle

Posted: Wed Aug 18, 2010 7:05 am

by Hombrey

Ok thanks for the info and I kinda agree it does sound like diff but assumed getting it fixed and paying $1300 in the process should solve that sort of stuff!! Anyway, so sounds like its not a wheel bearing or the other thing I was concerned about was driveshaft. Had checked that and found the uni's were both real clunky so replaced both but the sounds still there. Also a vibration at about 90k, which goes away at 100 or below 80?? But from what I've read lots of GQ's lifted a couple of inches do that. Its on 33inch wranglers.

Re: the print out for the rear axle

Posted: Wed Aug 18, 2010 7:32 am

by albundy

Ok thanks for the info and I kinda agree it does sound like diff but assumed getting it fixed and paying $1300 in the process should solve that sort of stuff!! Anyway, so sounds like its not a wheel bearing or the other thing I was concerned about was driveshaft. Had checked that and found the uni's were both real clunky so replaced both but the sounds still there. Also a vibration at about 90k, which goes away at 100 or below 80?? But from what I've read lots of

GQ's lifted a couple of inches do that. Its on 33inch wranglers.

Ok thanks for the info and I kinda agree it does sound like diff but assumed getting it fixed and paying $1300 in the process should solve that sort of stuff!! Anyway, so sounds like its not a wheel bearing or the other thing I was concerned about was driveshaft. Had checked that and found the uni's were both real clunky so replaced both but the sounds still there. Also a vibration at about 90k, which goes away at 100 or below 80?? But from what I've read lots of GQ's lifted a couple of inches do that. Its on 33inch wranglers.

Have you got gearbox spacers fitted? The vibration at 80K's, is it in the back or front?

Al

Re: the print out for the rear axle

Posted: Wed Aug 18, 2010 10:36 am

by darinz

If you have fitted new UJ then you shouldn't get vibs with a small lift. If you do then a GB packer should solve it cheaply (although not the right way to do it really)

There is no reason a GQ should have any vibs at all. It is a sign that something isn't working properly and needs replacing.

As for bent axles, everyone reinforces the front axles and yet the back also takes a huge pounding. I'm build a rather big gusset into mine as part of the 4 link conversion.

Re: the print out for the rear axle

Posted: Fri Aug 20, 2010 1:31 pm

by Hombrey

Feels like the vibe is coming from the rear. No no gearbox spacers but the vibe aligns with the knobs on gearbox wobbling a bit?? I've read about the driveshafts needing to be balanced as a unit. Given the trucks been doing it pretty much since I;ve owned it (2 years) plus has been worked on before would a driveshaft out of balance be the cause?

Re: the print out for the rear axle

Posted: Fri Aug 20, 2010 2:22 pm

by IcedJohnno

Driveshafts have several requirements

1) Input and output flanges correctly phased at the UJ's They must flex in the same directions exactly not 10 or 90 degrees out. (Very important and not obvious unless you look hard)

2) UJ's in good order

3) All components are straight

4) Driveshaft has been balanced as a unit

5) spline joint in good order, not too short for extended travel, and not binding via grit or too much grease at inner end of splined joint. (The latter has happened to Albundys Saffi before he owned it)

Another issue for 4wdrivers is that the UJ's are capable of taking the angles that the suspension travel puts the system through.

Re: the print out for the rear axle

Posted: Fri Aug 20, 2010 2:41 pm

by Hombrey

Re joints aligned correctly. So are the yokes suppose to be oriented the same way at each end i.e. aligned? Have had mine out to install new Universals but did not slide the spline apart which I assume is the only way for them to become misaligned?

Re: the print out for the rear axle

Posted: Mon Aug 23, 2010 10:15 am

by darinz

As a UJ bends it changes speed so the greater the angle they move through the greater speed change and the potential for vibes.

One theory is if you have the UJ's opposite then the driveshaft will have a more constant speed and so less chance for vibes as a lower speed change due movement.

But you could also argue that if they are opposite then the UJ's are fighting each other. So if the are in sinc then the drive shaft may change speed by more but the UJ's will be acting together.

So I say look at what you have and change it to the other unless someone can show which way is better?

So besides everything else this is why you want the UJ angle is as close to the magic 6* as possible even if the input and ouput flanges are parrallel. It is also why 4 (5) link rear ends have shorter top arms to point the pinion at the diff during suspension cycle. Yes it takes flanges out for parrallel but it also reduces overall angle so it is a case of lesser of 2 evils.