Fitting boost compensator to non turbo hilux pump

Posted: Mon Jan 13, 2014 9:21 pm

When putting a turbo on a non turbo 2l 3l or 5l it is best to fit a 2lt boost compensator to limit fuel off boost and improve fuel economy.

After a bit of unneeded shagging around I now have my truck running with the boost compensator on. When doing this I saw a few comments saying it was really easy but didn't find much else information.

So... here is what I found.

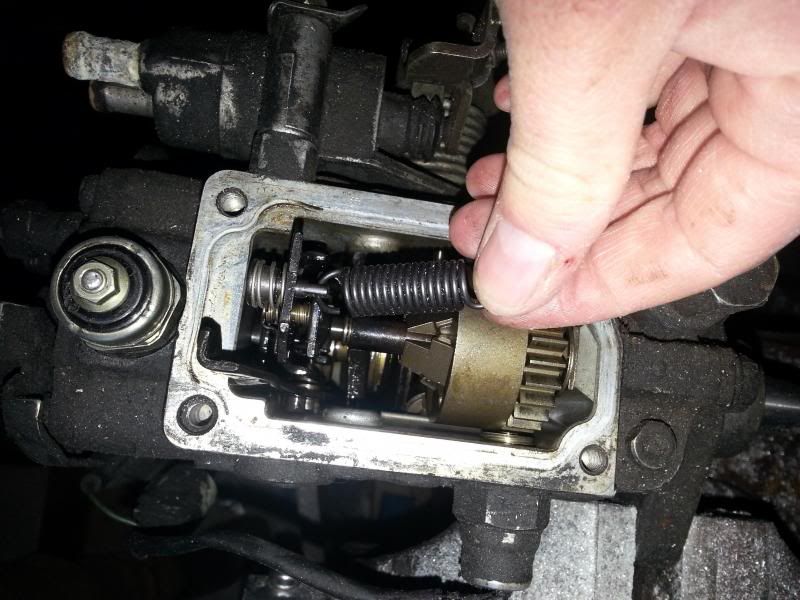

There are four cap screws holding the pump top hat on. Remove the whole top hat and swap it with the 2lt which will have the boost copmensator fitted. (needs to be non efi 2lt)

To get one of the cap screws undone I had to remove the throttle linkages on top of the pump. There are two plates. The top one has a spline on it. Mark from the top plate to the shaft and to the bottom plate (hopefully you get the chance to do this when removing the hat from the 2lt pump). I missed this when doing mine and decided to turn the shaft to min throttle position and put the plates in the min position as well. This resulted in the pump not letting any fuel to injectors when cranking with no throttle and not quite enough to start the engine when at full throttle. I moved the shaft about 3-4 teeth on the spline which was enough to get it started. It took off in revs and I moved it back one tooth at a time until it was right. Some of the shafts have a mark that you can line up with the top plate (the one off my 5l top had did but not the 2lt) Line this up and you should be pretty right.

I also had to remove the throttle linkages, idle speed screw and the max speed screw to get to cap screws.

Once you have the four cap screws off you can remove return fuel lines on the top hat and pull the hat up slightly. About a cup of fuel will come out.

The top hat will now be connected to the main pump but the throttle linkage spring. This is a bit of a pain to remove. I found pushing the top hat towards the motor and tipping it up I could see enough to remove the spring from the pump end (same for putting it back on).

Once you have the top had off the original pump you can fit the one with the boost comensator.

First refit the throttle linkage spring, fiddly but possible with the pump in place. (some have different spring arrangements. Both of my pumps had the same ones so I didn't have to worry but I think you would be best to keep the one that goes with the 2lt pump).

I then lined up the top had and put one of the cap screws back in to locate it. You will not be able to put the hat down fully as the max fuel screw will the sitting on top of the linkage. Put a long skinny screw driver in between the pump body and the top hat and push the max fuel linkage forward while pushing down on the pump slightly. When you get it forward enough the top hat will sit flush and you can put in the remaining cap screws. Re fit the throttle linkages and other bits.

Crack the injectors and crank the engine with the throttle full open. When fuel comes out nip up injector lines and see if it starts.

First draft - I will add some photos and update soon.

Cheers,

Pete

After a bit of unneeded shagging around I now have my truck running with the boost compensator on. When doing this I saw a few comments saying it was really easy but didn't find much else information.

So... here is what I found.

There are four cap screws holding the pump top hat on. Remove the whole top hat and swap it with the 2lt which will have the boost copmensator fitted. (needs to be non efi 2lt)

To get one of the cap screws undone I had to remove the throttle linkages on top of the pump. There are two plates. The top one has a spline on it. Mark from the top plate to the shaft and to the bottom plate (hopefully you get the chance to do this when removing the hat from the 2lt pump). I missed this when doing mine and decided to turn the shaft to min throttle position and put the plates in the min position as well. This resulted in the pump not letting any fuel to injectors when cranking with no throttle and not quite enough to start the engine when at full throttle. I moved the shaft about 3-4 teeth on the spline which was enough to get it started. It took off in revs and I moved it back one tooth at a time until it was right. Some of the shafts have a mark that you can line up with the top plate (the one off my 5l top had did but not the 2lt) Line this up and you should be pretty right.

I also had to remove the throttle linkages, idle speed screw and the max speed screw to get to cap screws.

Once you have the four cap screws off you can remove return fuel lines on the top hat and pull the hat up slightly. About a cup of fuel will come out.

The top hat will now be connected to the main pump but the throttle linkage spring. This is a bit of a pain to remove. I found pushing the top hat towards the motor and tipping it up I could see enough to remove the spring from the pump end (same for putting it back on).

Once you have the top had off the original pump you can fit the one with the boost comensator.

First refit the throttle linkage spring, fiddly but possible with the pump in place. (some have different spring arrangements. Both of my pumps had the same ones so I didn't have to worry but I think you would be best to keep the one that goes with the 2lt pump).

I then lined up the top had and put one of the cap screws back in to locate it. You will not be able to put the hat down fully as the max fuel screw will the sitting on top of the linkage. Put a long skinny screw driver in between the pump body and the top hat and push the max fuel linkage forward while pushing down on the pump slightly. When you get it forward enough the top hat will sit flush and you can put in the remaining cap screws. Re fit the throttle linkages and other bits.

Crack the injectors and crank the engine with the throttle full open. When fuel comes out nip up injector lines and see if it starts.

First draft - I will add some photos and update soon.

Cheers,

Pete