SJ416

Posted: Wed Jan 21, 2015 9:00 am

Hi all,

About 9 months ago the Mrs and I decided to get an SJ413 to use getting in to her home the Marlborough Sounds.

After a search on Trademe we found one in our price range, the photos looked tidy for its age and the owner said the only thing that would affect a warrant was the suspension bushes.

We were soon on the plane to Christchurch and after a short drive picked up our new project.

The winter drive up was less than comfortable with the heater intake sealed up to stop a leak, a big end that sounded like a heavy metal drummer and a carburettor that was about as airtight as a cheese grater. It was a quick schooling on carb icing too - my previous Toyotas have had top mounted carbs so never seemed to have quite as much of a problem. We made it back to Blenheim however and after a refuel, a sleep, and new fluids/plugs/leads continued on to the outer reaches of the Sounds.

On the way we acquainted ourselves with the unbridled power of the 1324cc engine - the majority of the horses having bolted and the few remaining flailing away in the big end bearings.

We made it, somewhat surprisingly and were greeted at the top of the airstrip by some compatriots - including the first SJ413 registered in NZ. NZ000001 strangely has 970cc on its data plate, despite being a 413 and having its original G13A in it.

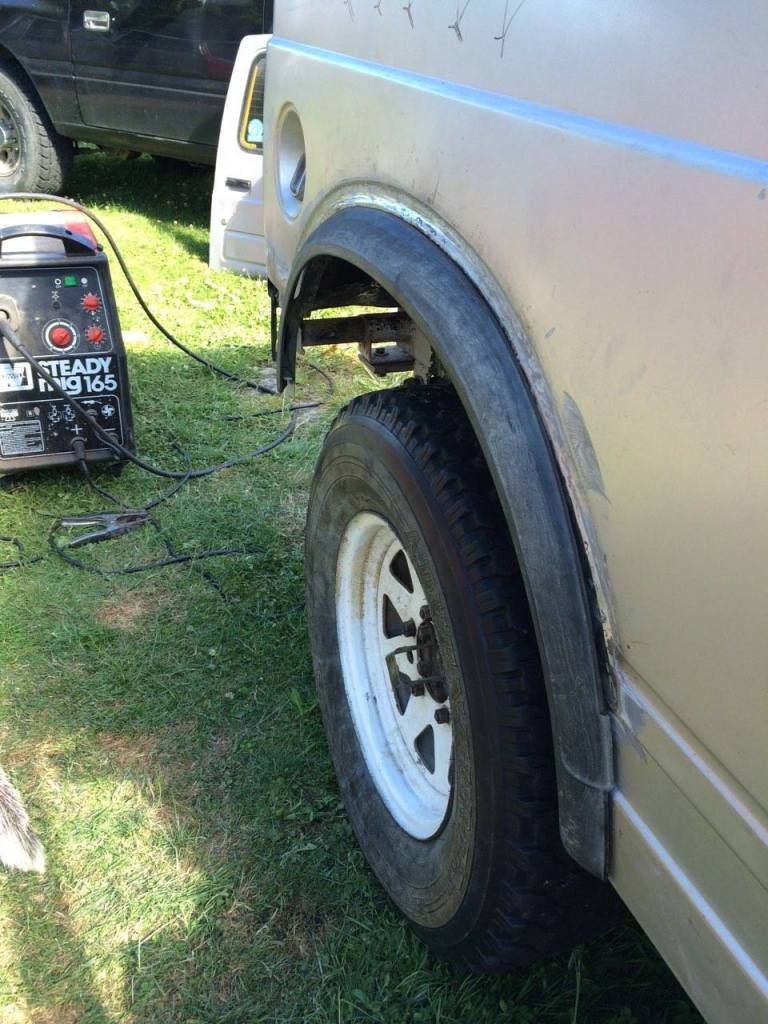

Over the course of the weekend things started going wrong. CV grease started leaking out of the swivel hubs, the transmission brake gave up the ghost etc etc etc - it was going to be a long few weeks sorting these bits and pieces out.

Back to civilisation and shortly new springs, shocks, swivel hub kits and bushings were on the way.

King pin bearings were in need of replacement, in fact one of the kingpins had snapped completely.

The initial part I was sent (2nd from right) was a real dud - no edge distance and holes drilled in flange by a monkey.

The crush tubes and bolts holding the springs in were all welded, requiring hard work with a hacksaw. Oddly, the suspension bushings I got didn't come with crush tubes - it was a nightmare finding some so I got some made up at Eckford engineering. I stayed away from Nolathane etc. for the time being as I want to keep it reasonably flexible.

CV and axle shaft were difficult to separate, I went to the local scrapyard and got a length of pipe.

No wonder I couldn't get it off with a hammer - eventually when it did budge it did this...

About 9 months ago the Mrs and I decided to get an SJ413 to use getting in to her home the Marlborough Sounds.

After a search on Trademe we found one in our price range, the photos looked tidy for its age and the owner said the only thing that would affect a warrant was the suspension bushes.

We were soon on the plane to Christchurch and after a short drive picked up our new project.

The winter drive up was less than comfortable with the heater intake sealed up to stop a leak, a big end that sounded like a heavy metal drummer and a carburettor that was about as airtight as a cheese grater. It was a quick schooling on carb icing too - my previous Toyotas have had top mounted carbs so never seemed to have quite as much of a problem. We made it back to Blenheim however and after a refuel, a sleep, and new fluids/plugs/leads continued on to the outer reaches of the Sounds.

On the way we acquainted ourselves with the unbridled power of the 1324cc engine - the majority of the horses having bolted and the few remaining flailing away in the big end bearings.

We made it, somewhat surprisingly and were greeted at the top of the airstrip by some compatriots - including the first SJ413 registered in NZ. NZ000001 strangely has 970cc on its data plate, despite being a 413 and having its original G13A in it.

Over the course of the weekend things started going wrong. CV grease started leaking out of the swivel hubs, the transmission brake gave up the ghost etc etc etc - it was going to be a long few weeks sorting these bits and pieces out.

Back to civilisation and shortly new springs, shocks, swivel hub kits and bushings were on the way.

King pin bearings were in need of replacement, in fact one of the kingpins had snapped completely.

The initial part I was sent (2nd from right) was a real dud - no edge distance and holes drilled in flange by a monkey.

The crush tubes and bolts holding the springs in were all welded, requiring hard work with a hacksaw. Oddly, the suspension bushings I got didn't come with crush tubes - it was a nightmare finding some so I got some made up at Eckford engineering. I stayed away from Nolathane etc. for the time being as I want to keep it reasonably flexible.

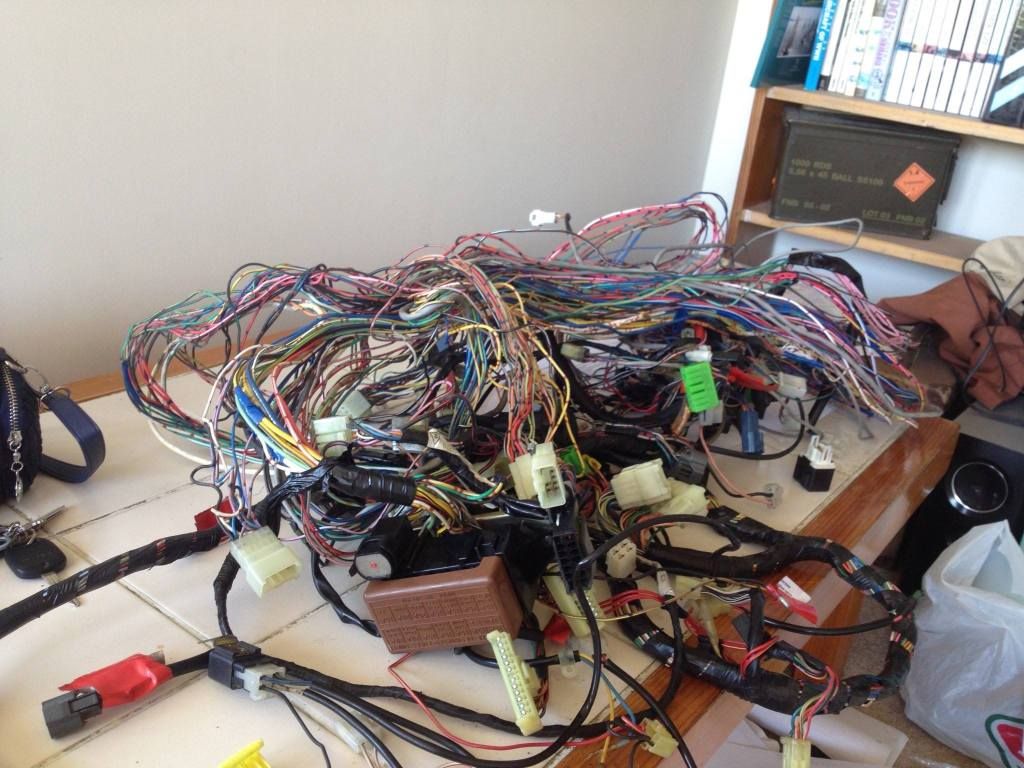

CV and axle shaft were difficult to separate, I went to the local scrapyard and got a length of pipe.

No wonder I couldn't get it off with a hammer - eventually when it did budge it did this...