cool__bananas wrote:2.6L v8? tell me more

who said v?

i was waiting for that

prob with total fluid sustem is heat, to be able too turn it on and off needs circulation, means complicated plumbing

v8 bike runs alky and no cooling so like a 60 sec wonder, fluid drive only has to deal with one engagement not repeated.

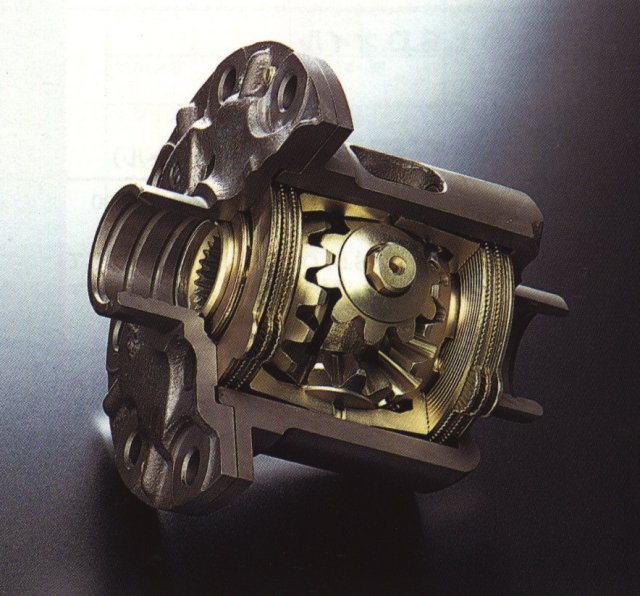

motorcycle sourced clutch with outer hub fixed to wheel, inner driving with axle/ cv is going to be best, outer mounted fluid release bearing pushing pressure plate.

bike clutches run approx 3.1 from engine, so 1000cc 170hp bike engine has huge mechincal advanatge over clutch, and has huge surface area compared to car type engine

1.1 as on single 35inch wheel, and run dry such as ducati etc, would handle it.

makes replacement plates readily available too

i think best way is too build 2x units and mount them to back of zuk, which also runs hilux axles (nissan diff head,)

for tesing.

um i run a business 6days, and a small farm, so in my life, besides plans, nothing happens fast.

just in a few months when someone digs this post up and asks how its going.........................