Now Just one thing to remember this was all done & the guy fitted 15inch rims!!!!

Just so everyone reading knows, this following write up is not from the link i posted in the first post, i cant remember where i found this following write upSo here is a little contribution to all series owners who wish to build a disk conversion and enjoy the challenge of a DIY project. Sorry for this bit I have to state it so no one get all worked up if something goes wrong - disclaimer: use this information at your own risk, modifying automobile brake systems can lead to dangerous situations, always have a trained mechanic or engineer check your work, I take no responsibility for the results, you've been warned, you're on your own..

With that behind us now we can get to the nitty gritty of this topic.

Let me start off by weighing some of the options out there for achieving disk brakes on a series, let’s start with the easy bit

A)Kits - horribly over priced, but will fit with relative ease, all the engineering has been done for you, can be done by anyone who can handle a spanner.

B)Disk brake axles (coil sprung vehicles) - Can be done but with some head scratching along the way, I know as I did one for someone else. The down fall in this is the ratios are different in the diffs (diff change), plus getting them to work with leafs will create a steering issue of which I will not further into, there is a lot of cutting and grinding involved and they are heavy to handle, but it can be done. Welding and fitting skills required, not for unskilled!

C) As above but go all the way and coil the vehicle, which might put you where point a is, considering the cost involved and the work required, this option might be out of the question all together, plus welding and fitting skills are a must, not for unskilled!

D)Mating coiler swivels, hubs and disks to a series axle – Can be done but you might end up with having custom shafts made, unless you put you hands on a stage 1 v8 axle. That will sort your shaft issues but will end up in the same area as point b, steering troubles. I could have achieved this as I run a stage 1 v8 front axle, but the steering bit was an area I did not feel I should venture to achieve disks.

E) Make your own kit as cheap as possible

All of the above just did not suit my pocket, I do have the skills know how for the other 3 options but I thought it was too much work just to achieve disk brakes. Bring on the challenge, option e! I had researched the net and found out that others have achieved this in one way or another, by using other disks and calipers (as do most of the kits). The real challenge was doing it with Landover parts! Why? Because a) I managed to get a free set of 90 calipers and parts are readily available. I know this made my life a bit more difficult, but the final result is very pleasing.

So onto the build, let me start by mentioning that I have a late stage 1 v8 axle, which for people seeing the pics and seeing some different bits might query. The axle is relatively the same as late series axles, apart the fact it runs CV’s. The same processes may be applied to early axles so do not despair!!

The initial spark for this project came in the form of a pair of free rusty calipers from a 98 300tdi defender90, which I upgraded to vented discs for a friend. These where in bad shape and need a complete rebuild, here are the results of a couple of weeks work with all the bits ready for reassembly.

The first stages where trying out other rover hubs and disks, all coiler hubs will fit my axle (this not the case with early axles), but they all had the disk in the wrong position, plus drive flanges did not match, etc, etc. So next up was to find a different disk from a diner other than a rover, many have been considered but none suited my needs, of buy and fit, they all required some machining here and there. So I found out after endless hours of measuring, I concluded that by using series hubs machined down I would gain valuable space to make a rover disc work.

Next came the choice of the rover disc, this was mainly determined by the caliper, using normal front discs did not work, they fit, but no space was left to make a descent bracket for the caliper. Rear discs where also tried, these gave some space but lacked the diameter. After another session of trawling the net for suitable discs I found a rover disc which fit my criteria nicely. The answer came from the late defenders new rear axle (non Salisbury type).

Now as I removed the drum I was left with a space to fill just to ensure I regain the few mm of track lost, so I got an old set of drums and turned them down to make a set of spacers.

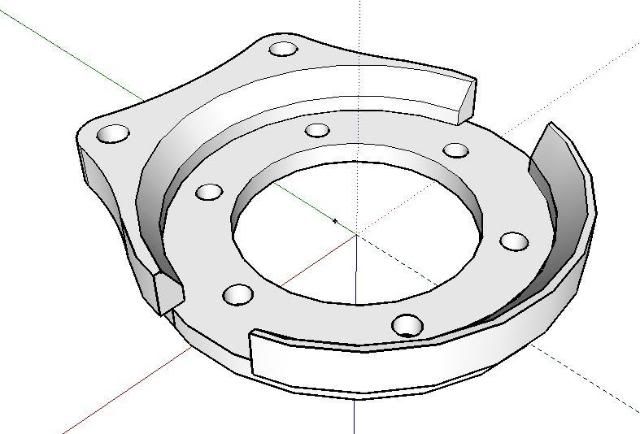

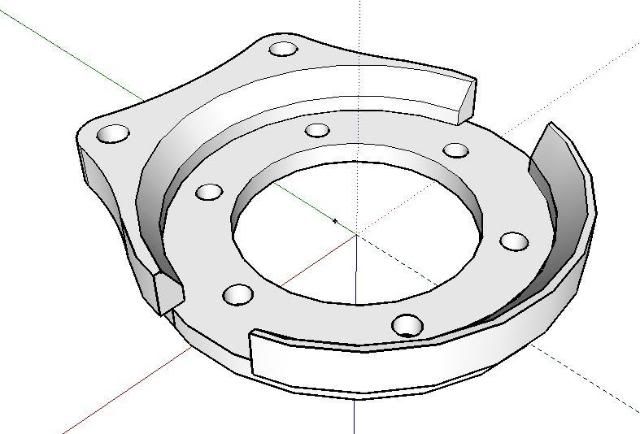

Machined hub and spacer

This disc left enough space for the caliper to squeeze in without interfering with the mounting face of the wheel rim. Having mentioned the wheel rims, I need to advise you that I run 15” white wheelers or early disco steel wheels, I have not yet tried standard series wheels and these might not work!! So having the right parts in hand I set out to create a mockup of the whole thing, not just thoughts in my brain, just to see if it might work. So first off I had a complete swivel housing mounted on the swivel that could be sacrificed for the cause.

I mounted up the disc to the newly machined hub and then mounted that to the stub axle and mock up assembly.

Hub and disc assembled

After seeing that I could squeeze in a sort of bracket I went on to fabricate one out of plywood and mdf, which resulted in to a sort of bracket I could get my bearings off. I tried to clock the caliper round the swivel housing to mount it like a defender but there was no way I could grind down and squeeze the caliper in, plus leaving space to access the mounting bolts. So the caliper ended up in the 12’o clock position. This left enough space for everything to fit!

Then I mounted it all together to see where I was. I did over react with the grinder on the mock up swivel as seen in the pics but in the final assembly not much grinding is required. The swivels need to be ground down to clear access to the bolts, there is no other way I could think of.

Right, with that done it all seemed to work so it was off to the engineer to have the bracket made out of metal. A couple months later the brackets turned up, not exactly as I wanted them but I lumped it and took them back home. So I first offered them up to the mock up and it all fitted well. Next stage was to get onto my landy, it all started coming together at this point.

From this point on things got a bit out of hand and I sadly discovered that the bracket for the other side was done completely wrong, clocked badly, etc, etc. Being angry was putting it mildly, so off I went to the engineers to have another one made. While I was there I thought that now was the time to remedy the mistakes done on the brackets. So I ordered another 2, with an improved design. After a further 2 weeks of discussions and ideas the below brackets where produced! Much joy and happiness settled in my garage as they looked the part and they fitted better than the ones before.

The 2nd set ready and trial fitted............Some pics of the progress, and new vs. old brackets.

It's all very tight.......

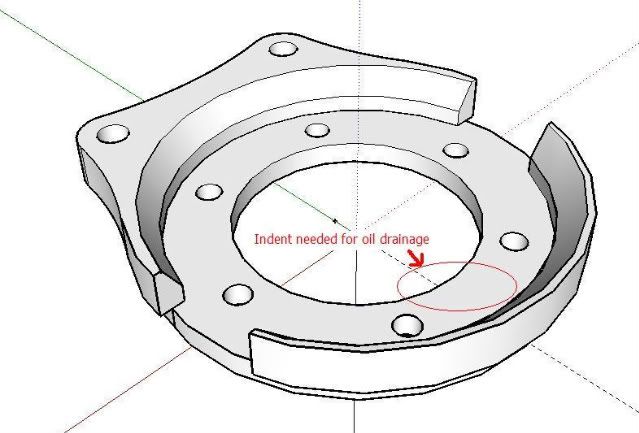

After I trial fitted these they came off once again for the final step, I made a slight indent in the face of the bracket which meets the stub so any oil leaks from the hub will go down that way. The stub axle also has the same as late series 3's had this to protect the drums from oil contamination. The same now applies for the discs, any oil leaks from the hubs will dribble behind the bracket leaving my pads and disks oil free! (I hope) I also made an oil retainer ring just as a precaution, this fits snugly with the hub making any oil go down the hole and keeping nasty things out of the oil seal

I also made the bolt holes for the caliper to contact the shank of the bolt so any stresses will be passed to the bolt shank and not the treads. I also made the brake pipe adaptors, bent to shape and ready for installation.

The whole thing together

Recess for bolt shank

Brake pipe

Now finally for the final assembly I gave the bracket a lick of flat black. The next pic is to show that also the caliper will need a slight grind.

The grinded swivel to clear the bolts

So with one side done I very pleased as it all came together nicely. Space between rim and caliper is tight but it all fits with 15" rims.

assembled

and a rear view showing rim

Now for the real world, do they work? Did they stop the landy?? how much did it all cost! And as many of you wish to know what are the part numbers for all the bits. Well I can only list what I have paid for, I am still waiting for the bill on the brackets.

It stops brilliantly and they were worth the effort of a whole year, on and off trying to get them done.

Most bits came for free as I had a lots of dead landy bits in the garage, like the hubs, mockup swivels and stub axles, the calipers came free, all I did was rebuild them and get new pads. They came off a 98 300tdi 90. Just rebuilding them cost me 35€ per caliper, then a set of pads was 30€, the retaining pin kit was about 7€. Next up the discs, they are from a Landover 110 2001> (non Salisbury axle) Part number is SDB000330, these cost me 70€ for the pair. The rest like bolts and pipes, grease and new oil seals came to around another 20€, so summing it all up it worked out under the 200€ mark, excluding the brackets. Even if these will cost me 100€ each ( which they will not), I still believe that this makes the whole exercise the most viable option.

Many of you out there will ask me for the dimensions and drawings, I am working on it, please be patient, here is a preview of where I got till now. If anybody follows what I did you can easily get there.

To conclude, if one wishes to use other disks and calipers he may freely do so, I could have made my life easier if I did that myself, especially with the calipers. In fact if I could find discs with 2-3mm larger in diameter but having the same hat dimensions I would be happier. But till now I am pretty happy to have got this far. I hope this little article has helped many people understand that it’s possible to have discs on a series using rover parts. If anybody requires any further info just let me know.