if its any consolation Chev its going to only be a cab and transfercase out of the zuk

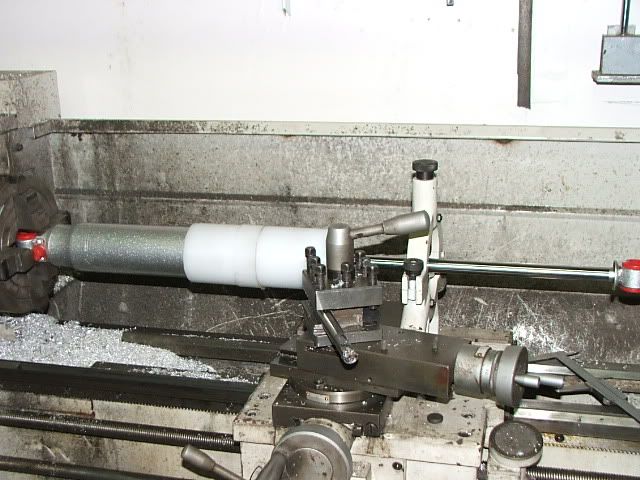

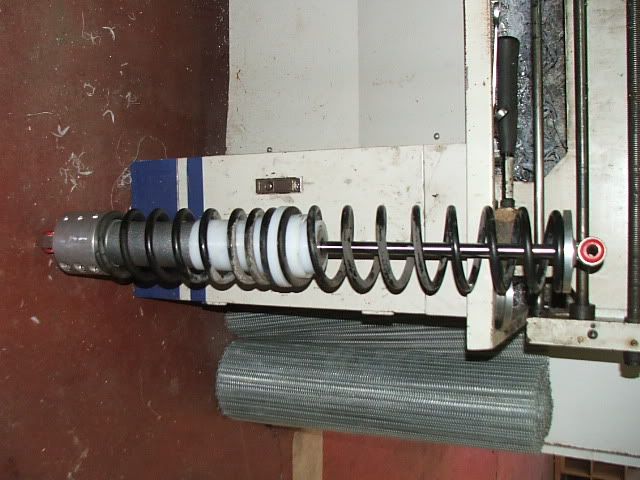

FB there's a bit more to come.... the long spring is my tender spring so I'm using a bit of tube cut to the length that stops the tender spring moving as it bottoms out on the slider

Since you guys asked

I'll start with a wee bit of basic spring 101, the coil spring is a patheticly simple design compaired to a leaf spring, the leaf is far superier performace wise... you can tune its rate at any piont in its compresion

problem for us with leaf springs is space, long travel means a long spring

So we go coil, this means we put up with shit performance just for long travel, the reason its shit is becouse its linear.... it has the same rate from the start of its compression to when it bottoms out eg 15kg per cm of travel

Yes there are progressive coils out there but its not something the average workshop can tune.. change the wire thickness, coil diameter, spacing/number of coils (this one you can use to increase the rate by cutting coils)

You've all seen those coils that get closer at one end.... progressive?

my experiance is most of these on cars are a gimic.... for these to work the closer spaced coils need to compact up till they are touching reducing the number of coils that are left to compress, easy way to see if its ever worked like this is the piant inbetween the coils will be gone

Calculating spring rate is easy

11250000 x (wire dia)4

Spring rate= --------------------------------

8 x # Active coils x (mean coil dia)3

# Active coils, this is the number of coils that arn't touching the spring seats

Mean coil dia , Dia of the coil measured from the centerline of the wire

Now I'm guessing your keen on a dual spring to try and get a longer spring for our long travel, or stiffer rate near full compression

spring rate 1 x spring rate 2

Combined spring rate = -------------------------------

spring rate 1 + spring rate 2

Calculating for a truck we need the sprung weight, this is the weight that sits on your suspension

In the case of my little truck, the front was 415kg, now add some pipe for exo, half the weight of two people and gear (half becouse we are in the middle of wheelbase so half our weight goes on the rear axle) and a few other bits I plan to do, gives me a front end sprung weight of 570kgs

Half that becouse we have a spring each corner = 285kgs

Now the fun begin's.... I wanted 60% of my travel to be down

60% x 300(shock length) = 18cm

285kg's (plus a bit for preload so springs don't fall out) / 18cm travel = 15kg's per cm traveled

Now you've got that your about to see why coil springs suck... times that rate by the full strock of the shock 450kg's... so all it takes is 165kgs to bottom out..... for road going you want it to be able to take (1gravity of impact) or twice its sprung weight 570kgs, this is why I need the dual rate

So I decide when the rate needs to ramp, say 80% of travel means I get 45mm of plush travel and 75mm of stiffer travel (catch is if you leave the change till later the secondary rate has to increase alot to bottom out at 1G, making for a harsh change)

75% x 450kgs = 337kg's so in the last 75mm of travel I need to stop 233kg's so I devide this by 7.5cm of travel and get 33kg per cm needed.... I decided to go with a slightly stiffer spring @39 as it gives me a bit of room to move ( and you need a bit of extra preload force on the springs to keep them captive at full extension)

Now to force this change of rate 15kg/cm to 39kg/cm you mount a bit of tube inside your tender spring to stop it compressing at the change piont

This is about as simple as you can make it

I've gotten so sick of doing these calc's I setup a spreadsheet as you compare springs... one effects the other so you have to recalculate

Now please understand I've simplified this ALOT

there is nothing about wheel rates, angle of your coilover or spring, with a beam axle to keep these effects to a minimim mount your springs/coilover as close to the wheel as possible and as close to vertical as you can and you'll be close enough