When putting a turbo on a non turbo 2l 3l or 5l it is best to fit a 2lt boost compensator to limit fuel off boost and improve fuel economy.

After a bit of unneeded shagging around I now have my truck running with the boost compensator on. When doing this I saw a few comments saying it was really easy but didn't find much else information.

So... here is what I found.

There are four cap screws holding the pump top hat on. Remove the whole top hat and swap it with the 2lt which will have the boost copmensator fitted. (needs to be non efi 2lt)

To get one of the cap screws undone I had to remove the throttle linkages on top of the pump. There are two plates. The top one has a spline on it. Mark from the top plate to the shaft and to the bottom plate (hopefully you get the chance to do this when removing the hat from the 2lt pump). I missed this when doing mine and decided to turn the shaft to min throttle position and put the plates in the min position as well. This resulted in the pump not letting any fuel to injectors when cranking with no throttle and not quite enough to start the engine when at full throttle. I moved the shaft about 3-4 teeth on the spline which was enough to get it started. It took off in revs and I moved it back one tooth at a time until it was right. Some of the shafts have a mark that you can line up with the top plate (the one off my 5l top had did but not the 2lt) Line this up and you should be pretty right.

I also had to remove the throttle linkages, idle speed screw and the max speed screw to get to cap screws.

Once you have the four cap screws off you can remove return fuel lines on the top hat and pull the hat up slightly. About a cup of fuel will come out.

The top hat will now be connected to the main pump but the throttle linkage spring. This is a bit of a pain to remove. I found pushing the top hat towards the motor and tipping it up I could see enough to remove the spring from the pump end (same for putting it back on).

Once you have the top had off the original pump you can fit the one with the boost comensator.

First refit the throttle linkage spring, fiddly but possible with the pump in place. (some have different spring arrangements. Both of my pumps had the same ones so I didn't have to worry but I think you would be best to keep the one that goes with the 2lt pump).

I then lined up the top had and put one of the cap screws back in to locate it. You will not be able to put the hat down fully as the max fuel screw will the sitting on top of the linkage. Put a long skinny screw driver in between the pump body and the top hat and push the max fuel linkage forward while pushing down on the pump slightly. When you get it forward enough the top hat will sit flush and you can put in the remaining cap screws. Re fit the throttle linkages and other bits.

Crack the injectors and crank the engine with the throttle full open. When fuel comes out nip up injector lines and see if it starts.

First draft - I will add some photos and update soon.

Cheers,

Pete

Fitting boost compensator to non turbo hilux pump

Re: Fitting boost compensator to non turbo hilux pump

And some photos...

This website has some great information on how the pumps works

http://www.cs.rochester.edu/u/jag/vw/en ... jpump.html

https://www.google.co.nz/url?sa=t&rct=j ... J7NE2n5ggw

2lt pump with 5l top hat on it. The normal 3l top hat is just flat but mine had an actuator of some sort on it. haven't really looked into how it worked but it didn't have the feed for intake pressure.

under side of 2lt top hat. Sowing throttle linkage with spring attached boost compensator linkage under the spring and the max fuel screw sticking through bottom left.

max fuel screw below banjo fitting and fuel cut solenoid below this

dirty 2lt pump with boost compensator still fitted

Throttle spring attached to the pump

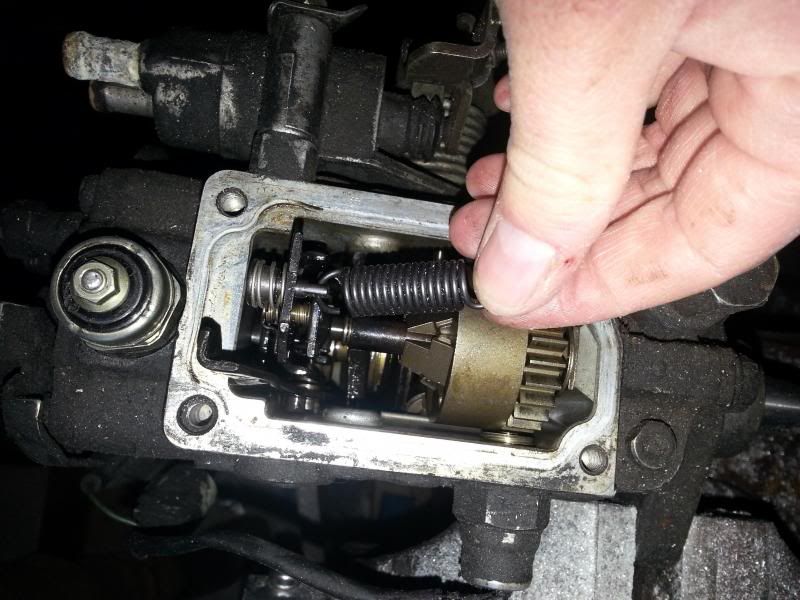

my finger is on the max fuel adjusting linkage this moves the starting point of the fuel bleed collar

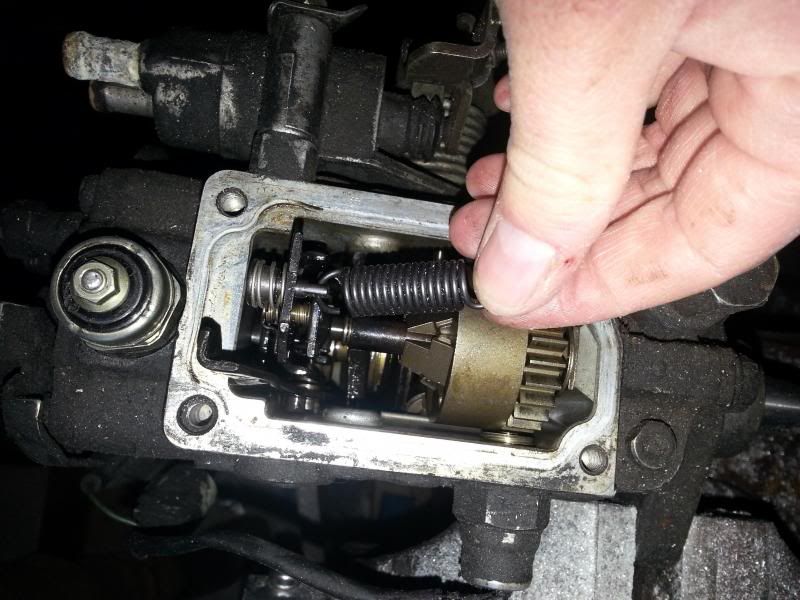

speed flyout weights. As the pump spins faster these fly out and push the plunger towards the back of the pump (I still can't quite work this out. it appears to lean out the pump when rmp increases..)

toothed wheel with prox pickup for rev counter.

boost compensator t'ed into boost gauge line off intake manifold

and a couple of crap vidoes

http://s958.photobucket.com/user/petemc ... 7.mp4.html

http://s958.photobucket.com/user/petemc ... state=copy

This website has some great information on how the pumps works

http://www.cs.rochester.edu/u/jag/vw/en ... jpump.html

https://www.google.co.nz/url?sa=t&rct=j ... J7NE2n5ggw

2lt pump with 5l top hat on it. The normal 3l top hat is just flat but mine had an actuator of some sort on it. haven't really looked into how it worked but it didn't have the feed for intake pressure.

under side of 2lt top hat. Sowing throttle linkage with spring attached boost compensator linkage under the spring and the max fuel screw sticking through bottom left.

max fuel screw below banjo fitting and fuel cut solenoid below this

dirty 2lt pump with boost compensator still fitted

Throttle spring attached to the pump

my finger is on the max fuel adjusting linkage this moves the starting point of the fuel bleed collar

speed flyout weights. As the pump spins faster these fly out and push the plunger towards the back of the pump (I still can't quite work this out. it appears to lean out the pump when rmp increases..)

toothed wheel with prox pickup for rev counter.

boost compensator t'ed into boost gauge line off intake manifold

and a couple of crap vidoes

http://s958.photobucket.com/user/petemc ... 7.mp4.html

http://s958.photobucket.com/user/petemc ... state=copy

Last edited by Petemcc on Tue Mar 31, 2015 6:01 am, edited 4 times in total.

Re: Fitting boost compensator to non turbo hilux pump

many thanks for the write up and pics

the 5l bit in the top hat is an altitude compensator.

the 5l bit in the top hat is an altitude compensator.

Re: Fitting boost compensator to non turbo hilux pump

oh yea that makes sense, good to know.

-

evilknieval69

- Bush Crasher

- Posts: 60

- Joined: Thu Sep 20, 2012 8:38 pm

Re: Fitting boost compensator to non turbo hilux pump

Once you take the throttle cable wheel bit off (the bit that you had on the wrong spline originally) you can just push that shaft down and it will come out of the top hat. Then when you lift the top off keep pushing it in and it will stay behind still connected via the spring. When you go to put the lid back on you just feed it into the hole first and push it throug, then assemble as normal. This way you don't have to try get underneath the top to disconnect the spring. A rubber o ring is all that holds the shaft in once you have taken the throttle wheel off.

Also, I usually put a long thin screw driver down the fuel screw hole once you have the top most of the way on and push the throttle plate with it through the hole. This way you can hold it right out whilst you seat the top right down on its seal, then remove the screw driver once you are holding it down.

Good write up, it is realy easy as long as you take note how things came off in the first place!

Also, I usually put a long thin screw driver down the fuel screw hole once you have the top most of the way on and push the throttle plate with it through the hole. This way you can hold it right out whilst you seat the top right down on its seal, then remove the screw driver once you are holding it down.

Good write up, it is realy easy as long as you take note how things came off in the first place!

- Im a Tumor

- Bush Crasher

- Posts: 77

- Joined: Sun Oct 27, 2013 5:07 pm

- Location: Christchurch

Re: Fitting boost compensator to non turbo hilux pump

Awesome write up guys!. Im looking to do this to my 3l when i turbo it hopefully in the near future

- Im a Tumor

- Bush Crasher

- Posts: 77

- Joined: Sun Oct 27, 2013 5:07 pm

- Location: Christchurch

Re: Fitting boost compensator to non turbo hilux pump

Finally did this yesterday. Awesome write up really helped.

One trick we found was removing the max fuel screw all together. Made fitting the comp to the 3l pump much easier.

Once the top hat was back on we just reinstalled it

One trick we found was removing the max fuel screw all together. Made fitting the comp to the 3l pump much easier.

Once the top hat was back on we just reinstalled it

-

sirLachlan

- Hard Yaka

- Posts: 109

- Joined: Sun Apr 03, 2016 8:28 am

Re: Fitting boost compensator to non turbo hilux pump

So does this actually work as you intend it to ? More fuel on boost and less fuel when off boost ?

Seems to be plenty of people who rekon it needs all the electronic shit to tell it what to do

It could be worth putting a nipple in the altitude sensor and using that . As in reality you are just feeding it a dense atmosphere by boosting it . When off boost it thinks your high in elevation and need less fuel

Could fine tine either setup with a bleed valve in the line to it

Seems to be plenty of people who rekon it needs all the electronic shit to tell it what to do

It could be worth putting a nipple in the altitude sensor and using that . As in reality you are just feeding it a dense atmosphere by boosting it . When off boost it thinks your high in elevation and need less fuel

Could fine tine either setup with a bleed valve in the line to it

-

sirLachlan

- Hard Yaka

- Posts: 109

- Joined: Sun Apr 03, 2016 8:28 am

Re: Fitting boost compensator to non turbo hilux pump

I guess its better to tune it with springs and the shape or rotation of the needle .

Now I want one

Having looked at the diagrams I dont think the altitude compensation has enough range to be usefull for boost . It has a sealed bellows in it aswell . Thought it might be a diaphram

Now I want one

Having looked at the diagrams I dont think the altitude compensation has enough range to be usefull for boost . It has a sealed bellows in it aswell . Thought it might be a diaphram